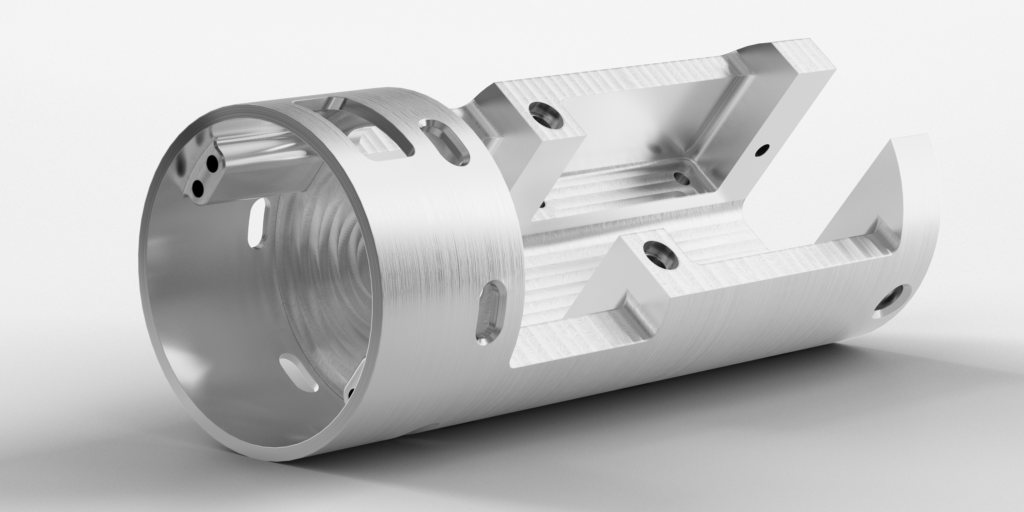

Production engineering reimagined, we make use of robotic automation across our CNC manufacturing.

Powered by cutting-edge software and the most modern equipment. Optimised to deliver the highest quality every time.

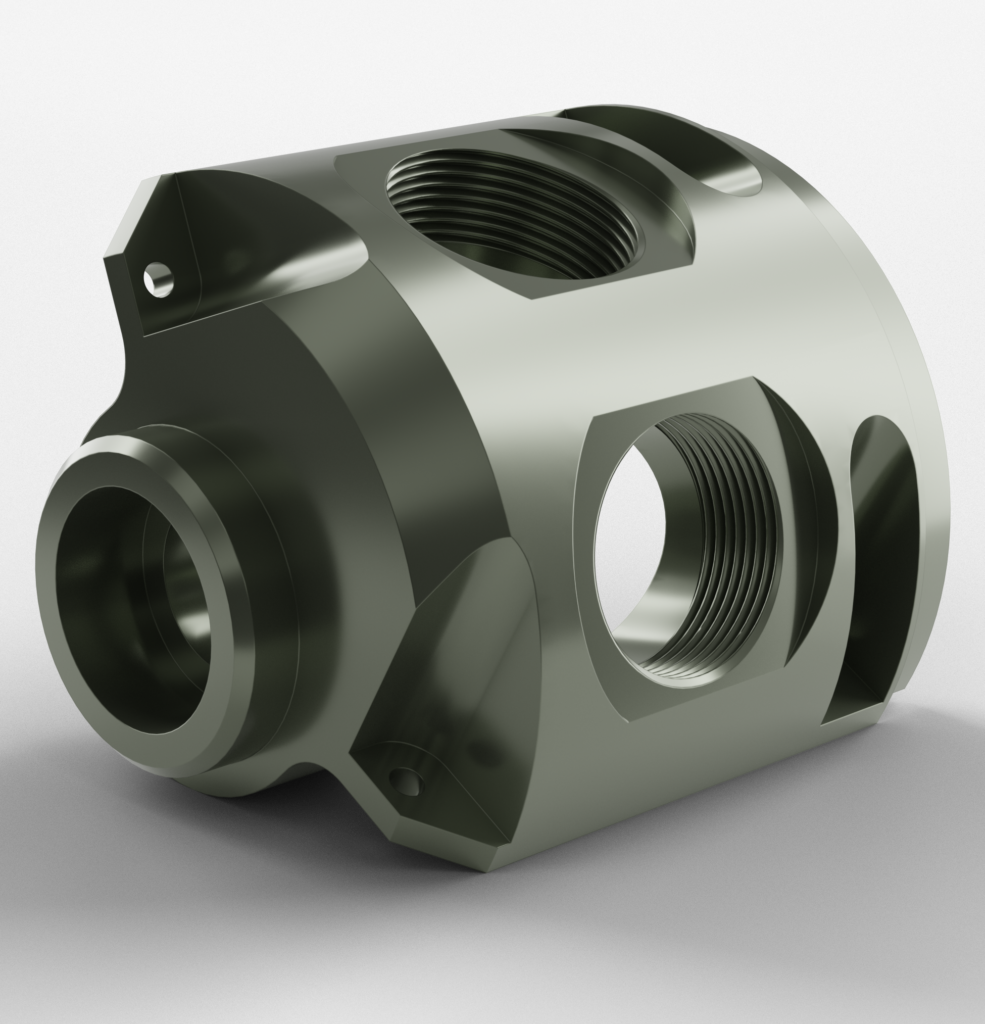

From our state-of-the-art factory in the UK, we supply high-spec precision-machined components to customers in a range of industrial sectors including Automotive, Defence, Aerospace & Space, Energy & Nuclear, and General Industry.

Precision manufacturing is fundamental to every aspect of modern life. In the modern world there is virtually nothing that can be made without precision parts. The manufacturing industry has been slow to modernise and adopt the innovations that are shaping our future.

We’re on a mission to automate manufacturing and create a clean and sustainable industrial revolution. We have built a factory of the future to make manufacturing more efficient, sustainable and faster than anything out there today.

We hire visionary people to work collectively to solve the most complex problems in manufacturing - to rethink, invent, optimise and automate at every level.

CloudNC can support you through every stage of production, from expert design for manufacture advice to prototyping, to high volume production.

Our tech team is developing cutting-edge machining science and AI to enable production efficiency and reliability never before seen in precision manufacturing.

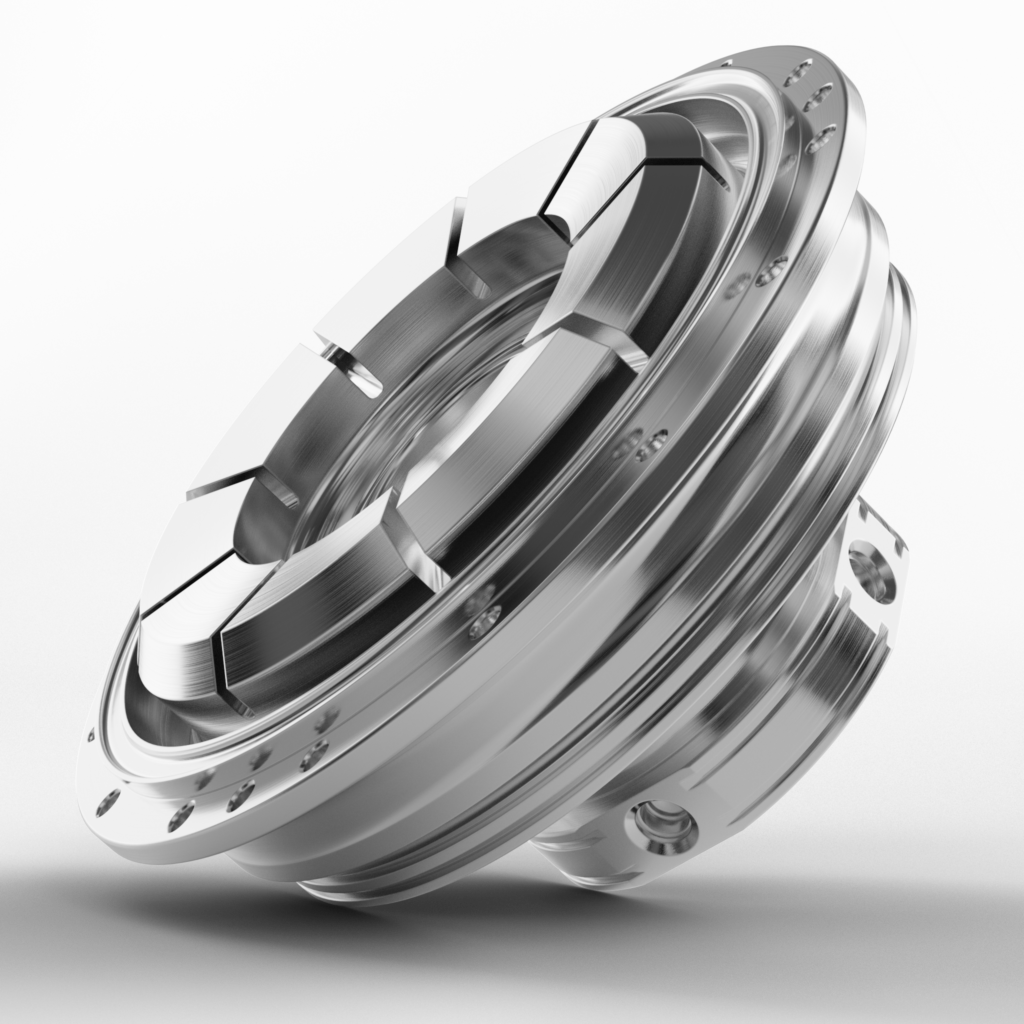

Our CNC milling machines range from 3-axis, 4-axis, 5-axis to 6-axis and are sourced from leading suppliers such as DMG, Mazak, Haas, and Fanuc.

EROWA automated feeder systems streamline and de-risk production for superhuman turnaround times and consistency – whether it’s an order of 1 or 1000s. We have inbuilt quality and inspection processes, with full AS9100D traceability, to ensure your parts arrive perfectly, on time, and in full.

CloudNC’s CNC turning capability produces precise parts from one-of-a-kind prototypes through to full-scale production.

We use exclusive innovative technology to turn a wide variety of materials into components of your exact specification and within schedule.

Our state-of-the-art DMG Mori machines are equipped with bar feeder and overhead robotic loading systems to cut out set up times between units and ensure your components are delivered to you when you expect them.

The perfect finish

We consider a full suite of finishing options to ensure your products meet your requirements.

Post-processing can change a surface finish, improve longevity and reduce costs. We will work with you to identify the right solution to suit your needs, using our supply partners where required.

At CloudNC we believe that quality is more than a process – it’s woven into our culture.

On-time in full (OTIF) and Quality are key performance drivers here. We are AS9100D certified, with full material traceability, inspection reports and material certificates supplied as standard.

Our air-conditioned quality assurance department employs a complete range of measurement and gauging equipment from globally recognised suppliers including Hexagon, Mitutoyo, and Bowers and we have recently acquired an Absolute 85 Arm, which enables reverse engineering capabilities and also allows for laser scanning of profile surfaces and other details.

We’re highly skilled and we use global and industry best practices. We work closely with our customers to achieve the highest standards they require.

We can provide full inspection reports, material certificates, process and control capability studies, and project-specific quality planning APOP, PPAP, and PFMEA.

Trimos V5 digital and motorised height gauge full probing kits

To contact us, please fill out the form below,

call us at 020 3966 5860

or email us at sales@cloudnc.com